Captain’s Log: Winter of 2016/2017

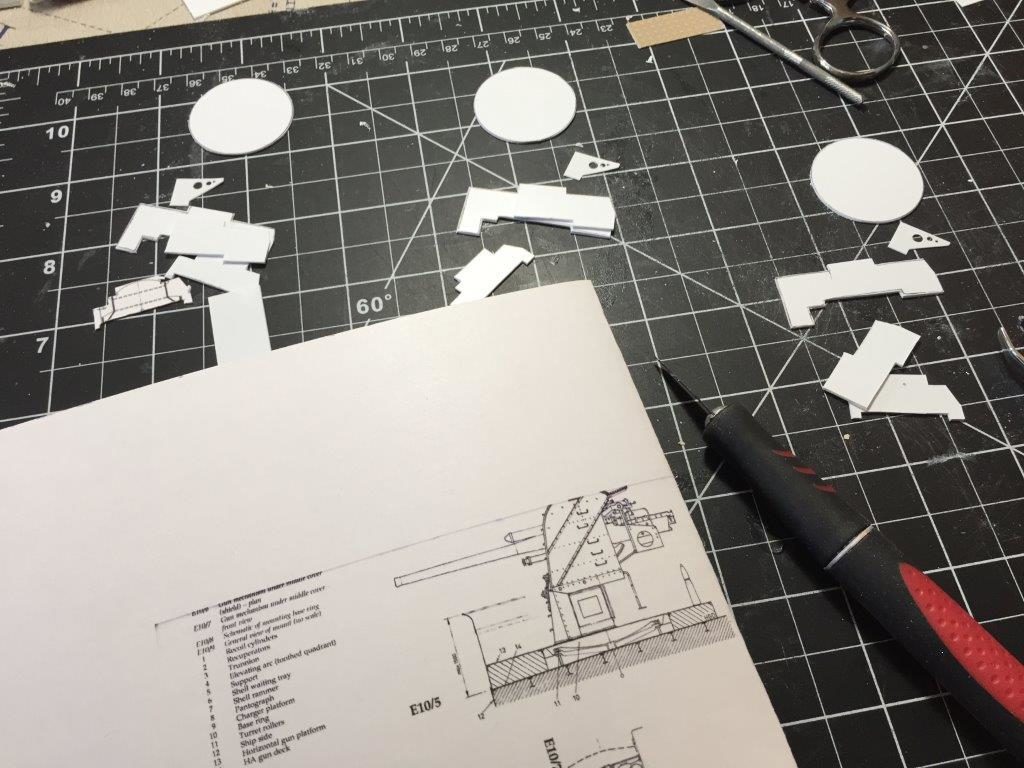

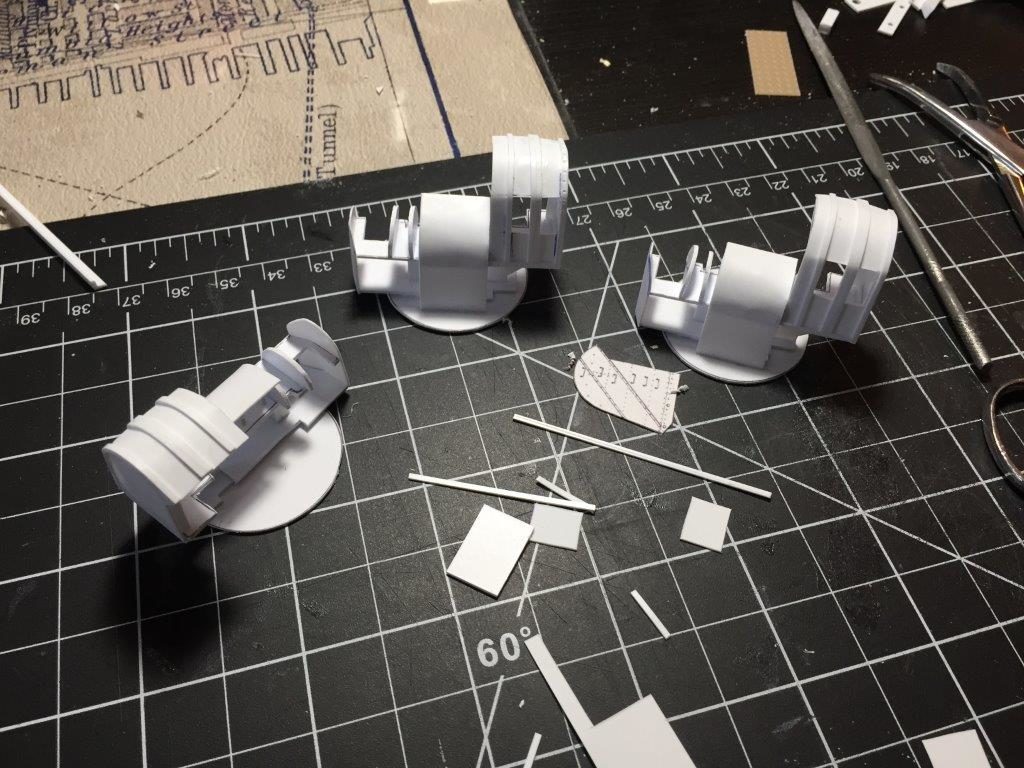

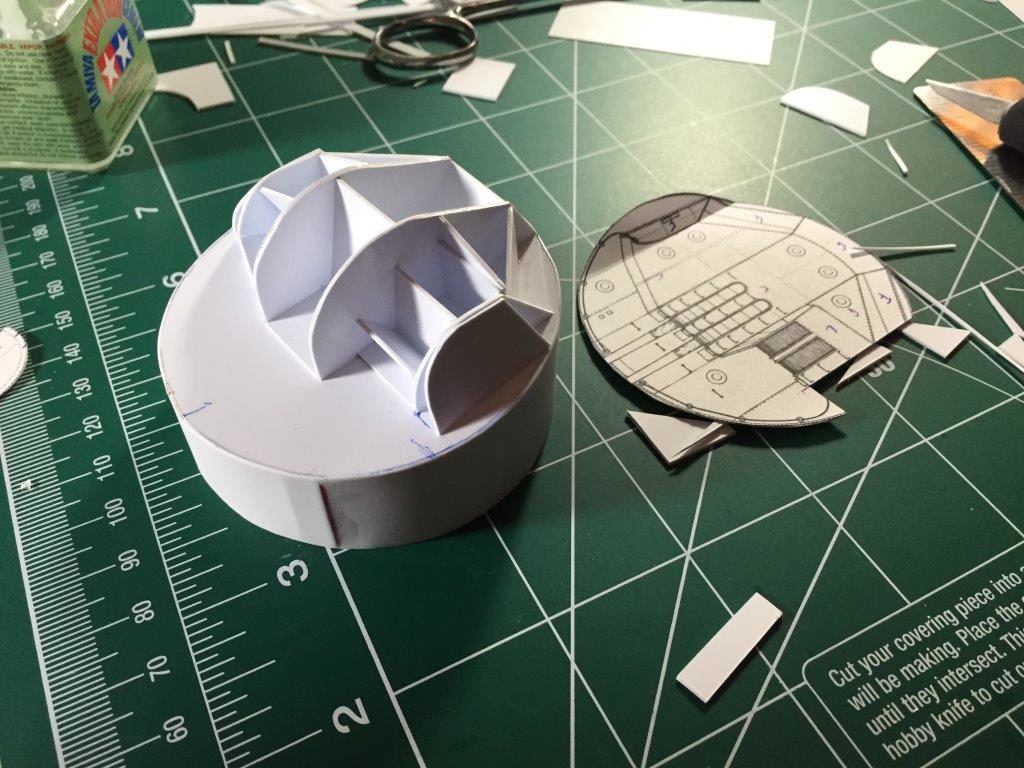

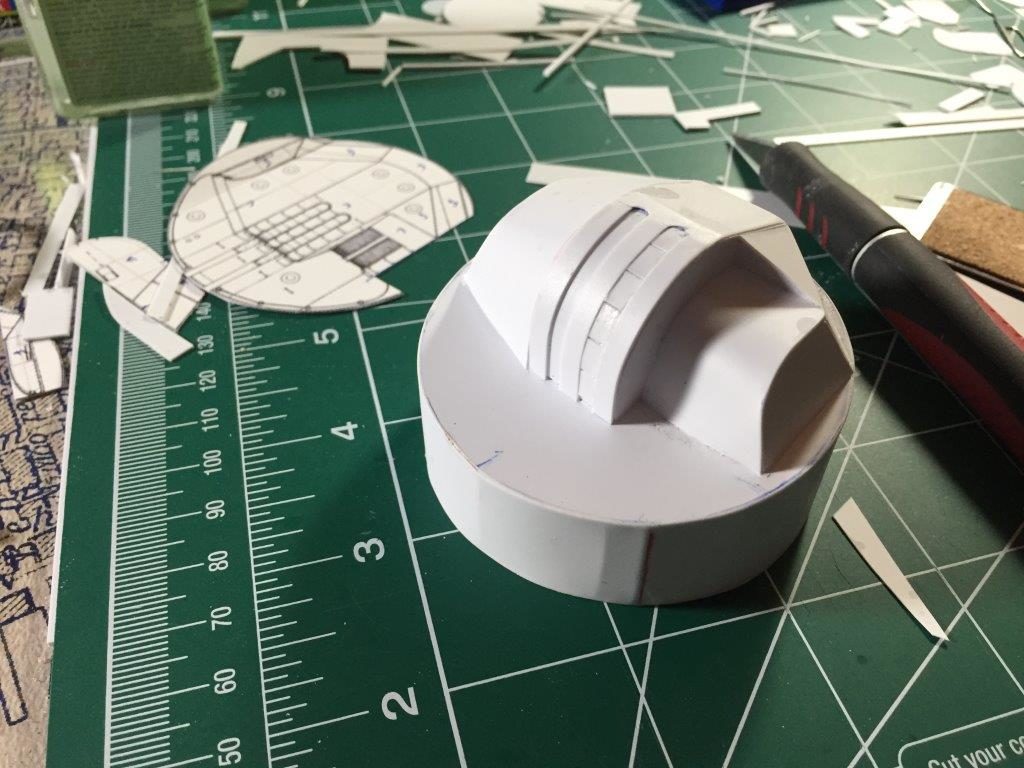

Next I moved on to the construction of Zuiho’s heavy weapons: the dual 5″ gun mounts. Printing out re-scaled drawings from AOTS Yamato helped immensely and the guns were completed in short order. Certain details were left off until I was nearly completed the kit. I didn’t want to add the fine details so early and have something snap off. The smoke shield covered 5″ gun was more of a challenge, but I think it turned out pretty good.

I then cut out sheets from the 4′ x 8′ roll of styrene I purchased and affixed them to the wood hull with a bio epoxy (a standard epoxy would have melted the styrene). This part was tricky as I had never worked with epoxy on wood or styrene. I got lucky and didn’t need to pull apart any parts of it. You only get one chance to attach them. This layer of styrene covered the sides and the bottom of the hull, but was too thick to be bent around the entire hull in the rounded edges. Once the thicker styrene set with the epoxy, I affixed thinner sheets (.05″) of styrene around the entire hull, effectively encasing it in styrene. As you will see in the forthcoming step 5 I then added strips of .01″ styrene to recreate the strakes that the actual ship had. So, by the time the ship was completed, she had three layers on styrene over the majority of the hull. To scale she has more belt and side armor than the actual ship! Once again the automotive filler and the sandpaper fixed any blemishes. You can see the first layer of styrene afixed to the hull sides in the two images below. She was officially a white elephant.

Captain’s Log: Spring of 2017

The next portion was tedious: cutting the hull strips and gluing them onto the hull to replicate the hull strakes. In hindsight, I should have pre-drilled the porthole holes into these strips before affixing them. I fretted over using alternating raised and recessed strakes, but the photographic evidence was wanting, especially for light and medium Japanese aircraft carriers. I opted for flush, joined strakes without the raised and recessed panels. From what I could tell, that is what the Japanese used on smaller ships, especially on regular hulled ships (not warships) and the Zuiho was converted from an oiler’s hull.

I added in the keels, propeller shafts and rudder and decided to paint the under-hull at this point. I figured that once I started building the sponsons and other upper hull attachments, it would be too much trouble to paint the lower hull later. I used 1 can of Tamiya primer and 2.5 cans of Tamiya Hull Red. I then gave the hull two coats of Future to further protect the paint. The final two coats were of Tamiya dull-coat spray. It looked really nice. It was great having some colour on her.

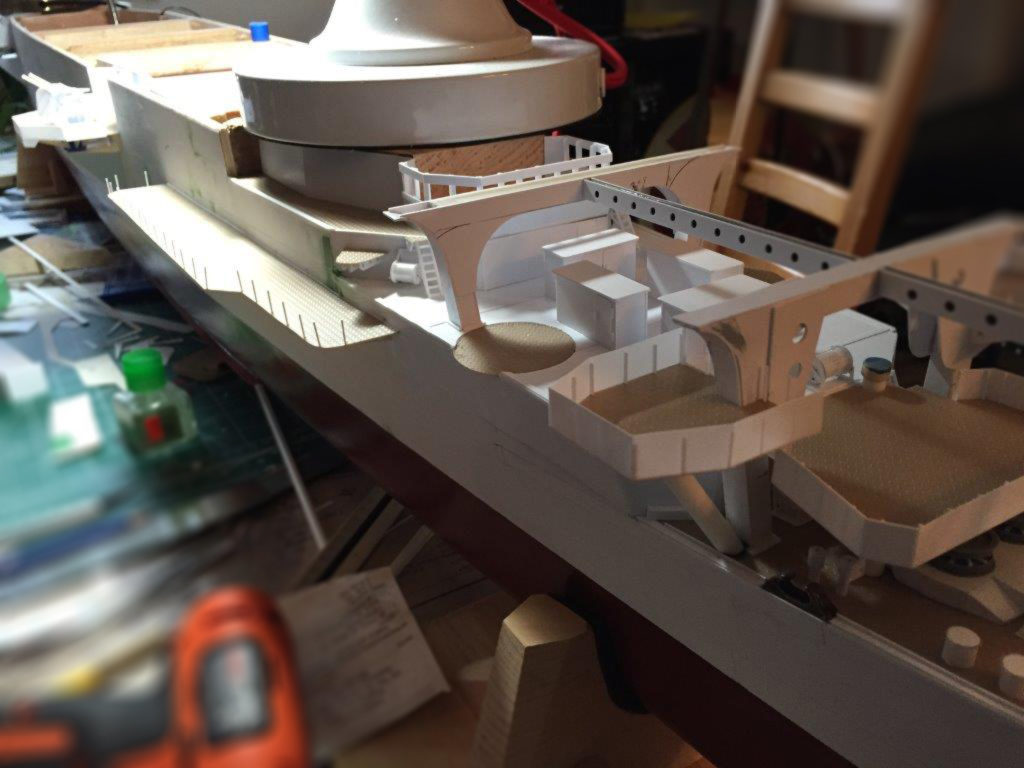

The next step was the sponsons, of which there were MANY! The support brackets were repetitive and challenging as they were rarely of uniform size because the sponson widths were rarely uniform. The sponsons, their enclosed structures and the eventual railings / shields were a large part of this build. I did not foresee the time and effort these areas of the ship would take. The three triple 25mm shielded mount sponson was completed at this time. I would find out later (through photographic evidence) that the sponson itself was not enclosed around the gun mounts, as is erroneously pictured below (The Fujimi 1/700 Zuiho has this enclosure on the kit). I still think it would’ve made sense to have the platform around the shielded triple 25mm guns covered to protect the crew from smoke as that is where all the ammunition handling occurs. Unfortunately, looking at that famous final image of her, it is pretty clear that such an enclosure is not in place.

The curved smoke stack was completed. Once again I used a wood core; cut, glued and sanded and then covered the stack in styrene. I tried several times to just used the styrene, but the bending and folding required of such thin styrene plus the Tamiya glue used saw the styrene tear every single time.